Assembly on July 16th 2004 - more pictures of the assembling

Visits: International Day July 25th 2004

In July 2004 the Lehrstuhl

für Tragkonstruktionen (institute for structural design) at the RWTH Aachen

(technical university of Aachen) will be planning and constructing

a bamboo dome of 12 m height for the international scouts camp

4u in Luxembourg. This project, initialised and taken charge of by

Dr.-Ing. Evelin Rottke (doctor of engineering) and Dipl.-Ing. Christoph

Tönges (graduate engineer) follows the institute´s tradition of developing

innovative constructions techniques and realising them in experimental

architecture, involving students from the design to the realisation of

the project.

On the 19th of June the construction was put to test in Lasauvage, Luxembourg,

without encountering any major problems.

On the 19th of June the construction was put to test in Lasauvage, Luxembourg, without encountering any major problems. The final set up will presumably take place on the 19th of July on the site of the scouts camp near Lasauvage / Luxembourg.

construction test

connection point with conical rods and metal joints

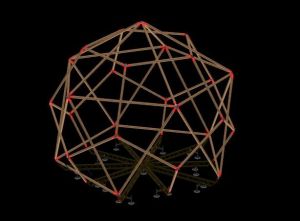

The design of the dome results from Christoph Tönges´ diploma , for which he examined the maximum length of bamboo rods in order to minimise the number of rods and joints. The resulting dome geometry is reduced to 50 poles, 31 joints and two rope-tied junctions, in which two poles stabilise each other. The dome in Luxembourg, which will not be covered by a roof, is constructed from rods with a maximum length of 8 m, creating a diameter of 15 m at ground level. The realisation of this project could not have taken place without the particularly well-working co-operation with the scouts of Luxembourg and their head Georges Schutz.

The realisation of this project could not have taken place

without the particularly well-working co-operation with the scouts of

Luxembourg and their head Georges Schutz.

All of the material was provided by sponsors. The high quality bamboo

Guadua Augustifolia was embarked in Columbia as additional cargo and transported

to Aachen. This was organised by Jörg Stamm, a german bamboo-constructor living

in South America and one of the institutes project partners. The connection

elements, which are grouted into the conical bamboo-ends, were made by

pupily of the technical highschool

Emile Metz. The grouting compound was and is being tested at the Université du Luxembourg.

Since the construction test passed without any problems, the dome will be set up in July and will be the landmark of the international scouts camp 4U. As the reusability of the rods is part of the construction principle, the dome will be rebuilt and used as an info-pavilion to a nature trail when the camp is over.

Dr.-Ing. Evelin

Rottke, RWTH Aachen

Dipl.-Ing. Christoph Tönges

Dipl.-Ing. Georges Schutz for the scouts of Luxembourg

manpower.

fibre-glass threads.

construction.

construction.

assembled first.

icosahedron and, therefore, of the dome, are

connected to the tension ring...

dodecahedron is tied to the construction.

its final height.

is tested...